|

|

|

|

Dexpan«

Non Explosive Controlled Demolition Agent

For Controlled

Demolition, Reinforced Concrete Cutting, Rock

Breaking, Quarrying,

Stone Dimension, Mining, Excavating ...

|

|

|

|

|

Dexpan 3 Easy Steps to succeed:

Drill, Mix and

Fill

Read safety and operation instruction CAREFULLY

before use Dexpan

Read safety and operation instruction CAREFULLY

before use Dexpan

Warning! Blowouts may occur! DO

NOT look directly into filled holes.

Warning! Blowouts may occur! DO

NOT look directly into filled holes.

Safety Goggles, Rubber Gloves and Dust-Proof Mask is

Required.

Safety Goggles, Rubber Gloves and Dust-Proof Mask is

Required.

For technical support,

call our toll-free

1-866-272-4378 or 575-874-9188 (United

States)

|

|

Dexpan

Preparation

|

|

|

|

Reinforced concrete

foundation, 3'x3'x2' |

|

Choose correct type of

Dexpan based on rock / concrete temperature. |

|

|

|

Safety goggles, dust mask, rubber gloves, long sleeve cloth are required.

Safety goggles, dust mask, rubber gloves, long sleeve cloth are required.

|

|

|

|

Dexpan

Step 1: Drilling

|

|

|

|

|

|

|

|

|

-

Drill holes using a

hammer drill and appropriate drill bit specific

to the rock or concrete type.

-

Holes should be

drilled no further than

1 ft (30 cm) apart.

Note: In reinforced concrete recommended no more

than 8 in (20 cm) apart.

-

Recommended hole

diameter is 1.5 inches (3.8 cm), not to exceed 2 in

(5 cm). Drill holes should be 80-90% of the

depth, do not go through.

|

|

|

|

Dexpan

Step 2: Mixing

|

|

|

|

|

|

|

|

-

In a flat bottom

bucket, combine 0.4 gallons (1.5 l) of water with

one 11 lb. (5 kgs) bag of

Dexpan«.

-

Mix well (a drill

and paddle is recommended). If mixing with a

stick or other method, make sure Dexpan«

is completely dissolved into the water. Mix to a

slurry.

|

|

|

|

Dexpan

Step 3: Filling

|

|

|

|

|

|

|

|

-

Warning! Use of

Dexpan in Extreme Hot Temperature could cause

blowouts.

Warning! Use of

Dexpan in Extreme Hot Temperature could cause

blowouts.

-

Clean holes before

filling. Using an air hose to remove excess dust

from drilling.

-

Dexpan«

slurry should be poured into holes within

10-15

minutes after mixing. Do not fill to the top,

only fill the holes about 1/2 to 1 inch (2.5 cm)

from the top.

-

Pour well mixed

Dexpan« slurry into holes. Agitating

the Dexpan« in the hole to make sure

no air is trapped in holes. Suggestion: Use a

rod or stick to poke holes.

-

A grout pump might

be required to fill horizontal holes. Caps might

be needed for horizontal holes, but only

necessary to hold Dexpan« in the

holes.

|

|

|

|

Dexpan

Coverage and

Cracking Time |

|

|

|

|

|

|

|

|

|

|

|

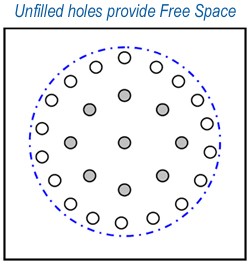

Dexpan Coverage:

Normally one 44 lbs (20

kgs) box of Dexpan« can fill up to

35

lineal feet (10 m) of 1.5 inches (3.8 cm) diameter

holes. You might not have to fill every hole

depending on application. |

|

|

|

Dexpan

Cracking or Cutting Time:

Properly mixed, the

cracks may appear after 2~8 hours of filling drilled

holes, depending on ambient temperature, humidity,

rock or concrete hardness. Give it

24 hours for best

results. |

|

|

|

WARNING!

IMPORTANT SAFETY PRECAUTIONS

and FIRST AID |

|

|

|

Read safety and operation instruction CAREFULLY. (

Go to

Dexpan Downloads )

Read safety and operation instruction CAREFULLY. (

Go to

Dexpan Downloads )

A pair of safety goggles,

rubber gloves and a

dust mask is REQUIRED. Avoid eyes, skin

contact. Do not breathe dust. If eye or skin contact

should occur, rinse it off IMMEDIATELY with plenty

of water for at least 20 minutes, and consult doctor.

A pair of safety goggles,

rubber gloves and a

dust mask is REQUIRED. Avoid eyes, skin

contact. Do not breathe dust. If eye or skin contact

should occur, rinse it off IMMEDIATELY with plenty

of water for at least 20 minutes, and consult doctor.

WARNING!

DO NOT look directly into filled holes as blowouts

may occur.

WARNING!

DO NOT look directly into filled holes as blowouts

may occur.

Keep Dexpan« in DRY storage. SEAL

Dexpan container after use.

Keep Dexpan« in DRY storage. SEAL

Dexpan container after use.

Select the correct type of Dexpan« based

on rock / concrete temperature.

Select the correct type of Dexpan« based

on rock / concrete temperature. |

|

|

|

Dexpan

Usage Tips |

|

|

|

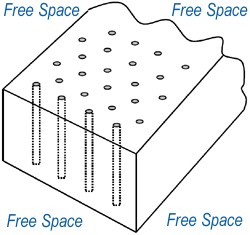

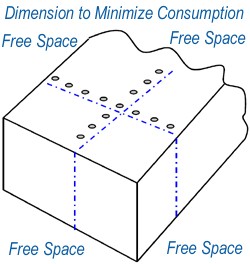

Well designed hole drilling pattern will minimize

consumption of Dexpan« by cutting into

desired sizes.

Well designed hole drilling pattern will minimize

consumption of Dexpan« by cutting into

desired sizes.

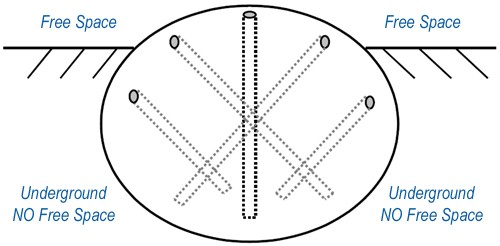

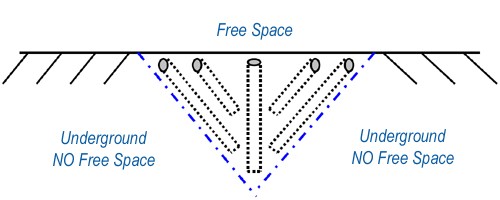

To insure success, Dexpan« needs free

space to expand to.

To insure success, Dexpan« needs free

space to expand to.

For better results, it is important to note both air

and material temperature. Material temperature is

the temperature inside of the rock or concrete which

can be different from the air temperature.

For better results, it is important to note both air

and material temperature. Material temperature is

the temperature inside of the rock or concrete which

can be different from the air temperature.

In summer, the best time to use Dexpan«

is in the morning or evening when material

temperature is cool.

In summer, the best time to use Dexpan«

is in the morning or evening when material

temperature is cool.

In summer, cover Dexpan holes from direct sunlight to avoid

blow-out. Example: using a tarp or damp hay to

provide shade.

In summer, cover Dexpan holes from direct sunlight to avoid

blow-out. Example: using a tarp or damp hay to

provide shade.

If Dexpan« completely dries into powder

and did NOT crack, pour additional water onto Dexpan«

filled holes.

If Dexpan« completely dries into powder

and did NOT crack, pour additional water onto Dexpan«

filled holes.

Wear goggles, blowouts may occur.

Wear goggles, blowouts may occur. |

|

|

|

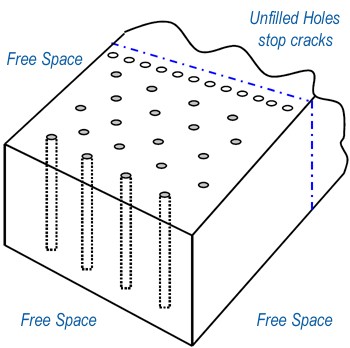

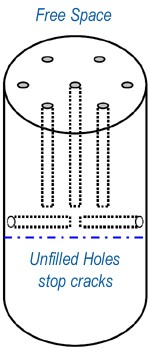

Dexpan

Drilling Designs |

|

|

|

Filled Hole |

|

|

Unfilled

Hole |

|

|

Desired Cutting Line |

|

|

|

|

|

|

|

|

|

|

[3] Cut into

desired size to lower cost |

[4] Tunneling |

|

|

|

|

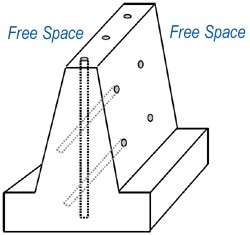

[5 (left)] Partial

Demolition with VERTICAL desired cutting line

[6 (right)] Partial

Demolition with HORIZONTAL desired cutting line |

|

|

|

[7] Underground

rock

excavation, dig around to provide free space |

|

|

|

[8] Trenching, do not

need to dig around |

Demolition Agent Dexpan,

Dexpan Non

Explosive Demolition Agent, Dexpan Silent Demolition,

Dexpan Controlled Demolition Agent for Non Explosive

Demolition,

Concrete Demolition, construction demolition, building

demolition, demolition DIY, demolition do it yourself

project,

Demolition

contractors. How to use Dexpan Non Explosive Controlled

Blasting Demolition Agent

|